Kufotokozera

Kuti mupange zomaliza zapamwamba pamtengo wotsika kwambiri komanso zodalirika, muyenera kusankha zida zovala zomwe zimakongoletsedwa ndi pulogalamu yanu yophwanya. Mfundo zazikuluzikulu zomwe muyenera kuziganizira motere:

1. Mtundu wa miyala kapena mchere woti uphwanyidwe.

2. Kukula kwa tinthu tating'onoting'ono, chinyezi ndi kalasi ya Mohs kuuma.

3. Zida ndi moyo wazitsulo zowombera zomwe zimagwiritsidwa ntchito kale.

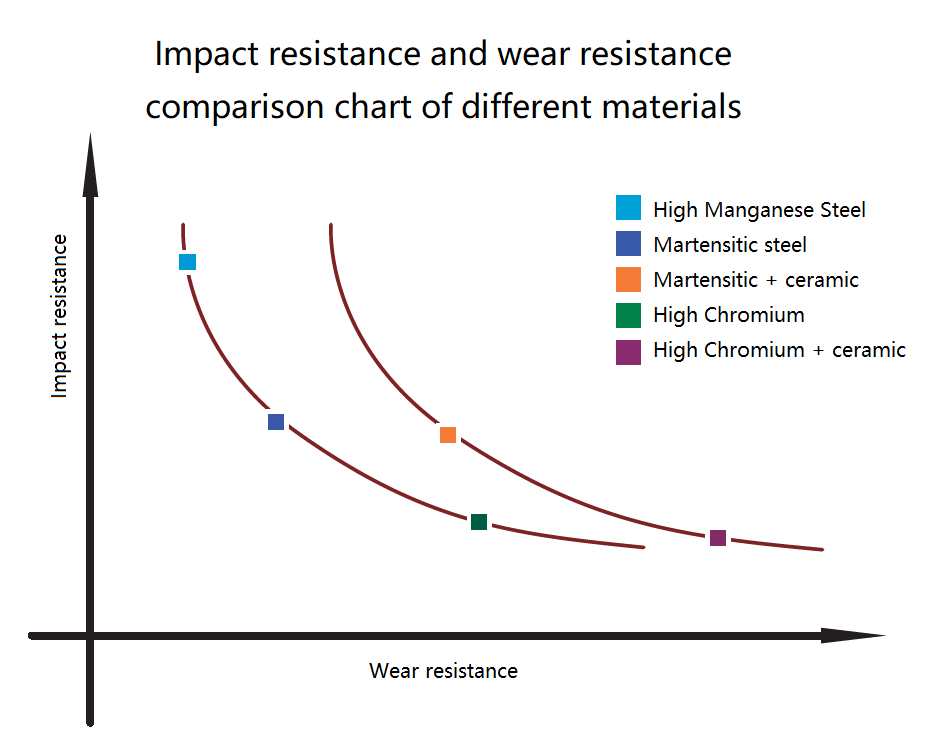

Nthawi zambiri, kukana kuvala (kapena kuuma) kwa zida zomangira zitsulo zokhala ndi khoma kudzachepetsa kukana kwake (kapena kulimba). Njira yophatikizira mbiya muzinthu zachitsulo zamatrix imatha kukulitsa kukana kwake popanda kukhudza kukana kwake.

Chitsulo chachikulu cha Manganese

Chitsulo chapamwamba cha manganese ndi chinthu chosamva kuvala cha mbiri yakale ndipo chakhala chikugwiritsidwa ntchito kwambiri pophwanya mphamvu. Chitsulo chokwera cha manganese chimakhala ndi mphamvu yokana kwambiri. Kukaniza kuvala nthawi zambiri kumakhudzana ndi kupanikizika ndi kukhudzidwa kwake. Mukakhudzidwa kwambiri, mawonekedwe a austenite pamtunda amatha kuumitsa mpaka HRC50 kapena kupitilira apo.

Nyundo zapamwamba zachitsulo za manganese nthawi zambiri zimangolimbikitsidwa kuti ziphwanyidwe ndi zinthu zakukula kwa tinthu tating'ono komanso kulimba kochepa.

Chemical zikuchokera mkulu manganese zitsulo

| Zakuthupi | Chemical Composition | Machanical Property | ||||

| Mn% | Cr% | C% | Si% | Ak/cm | HB | |

| Mn14 | 12-14 | 1.7-2.2 | 1.15-1.25 | 0.3-0.6 | > 140 | 180-220 |

| Mn15 | 14-16 | 1.7-2.2 | 1.15-1.30 | 0.3-0.6 | > 140 | 180-220 |

| Mn18 | 16-19 | 1.8-2.5 | 1.15-1.30 | 0.3-0.8 | > 140 | 190-240 |

| Mn22 | 20-22 | 1.8-2.5 | 1.10-1.40 | 0.3-0.8 | > 140 | 190-240 |

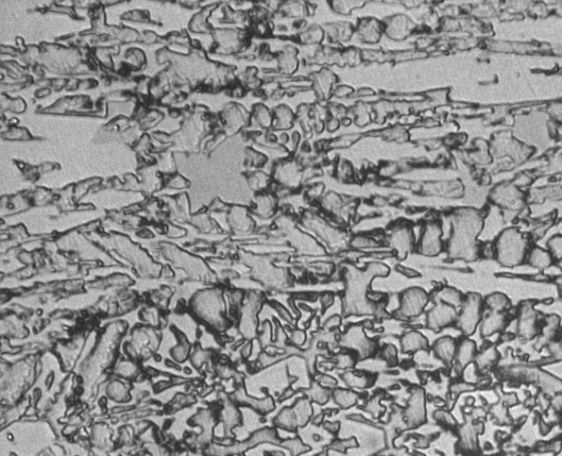

Microstructure ya high manganese chitsulo

Chitsulo cha Martensitic

Mapangidwe a Martensite amapangidwa ndi kuzizira kofulumira kwa chitsulo chodzaza mpweya. Ma atomu a carbon amatha kufalikira kuchokera ku martensite pokhapokha pozizira mofulumira pambuyo pa kutentha. Chitsulo cha Martensitic chimakhala cholimba kwambiri kuposa chitsulo chapamwamba cha manganese, koma kukana kwake kumachepanso. Kuuma kwachitsulo cha martensitic kuli pakati pa HRC46-56. Kutengera ndi zinthuzi, martensitic steel blow bar nthawi zambiri amalimbikitsidwa kuti aphwanye ntchito zomwe zimakhala zochepa koma kukana kwamphamvu kumafunikira.

Microstructure ya chitsulo cha martensitic

High Chromium White Iron

Mu chitsulo choyera cha chromium, mpweya umaphatikizidwa ndi chromium mu mawonekedwe a chromium carbide. Chitsulo choyera cha chromium chimakhala cholimba kwambiri. Pambuyo pa chithandizo cha kutentha, kuuma kwake kumatha kufika 60-64HRC, koma kukana kwake kumachepetsedwa. Poyerekeza ndi chitsulo chochuluka cha manganese ndi chitsulo cha martensitic, chitsulo chokwera kwambiri cha chromium chimakhala ndi kukana kwamphamvu kwambiri, koma kukana kwake ndikotsika kwambiri.

Mu chitsulo choyera cha chromium, mpweya umaphatikizidwa ndi chromium mu mawonekedwe a chromium carbide. Chitsulo choyera cha chromium chimakhala cholimba kwambiri. Pambuyo pa chithandizo cha kutentha, kuuma kwake kumatha kufika 60-64HRC, koma kukana kwake kumachepetsedwa. Poyerekeza ndi chitsulo chochuluka cha manganese ndi chitsulo cha martensitic, chitsulo chokwera kwambiri cha chromium chimakhala ndi kukana kwamphamvu kwambiri, koma kukana kwake ndikotsika kwambiri.

Chemical zikuchokera mkulu chromium woyera chitsulo

| Chithunzi cha ASTM A532 | Kufotokozera | C | Mn | Si | Ni | Cr | Mo | |

| I | A | Ni-Cr-Hc | 2.8-3.6 | 2.0 Max | 0.8 max | 3.3-5.0 | 1.4-4.0 | 1.0 Max |

| I | B | Ndi-Cr-Lc | 2.4-3.0 | 2.0 Max | 0.8 max | 3.3-5.0 | 1.4-4.0 | 1.0 Max |

| I | C | Ndi-Cr-GB | 2.5-3.7 | 2.0 Max | 0.8 max | 4.0 Max | 1.0-2.5 | 1.0 Max |

| I | D | Ndi-HiCr | 2.5-3.6 | 2.0 Max | 2.0 Max | 4.5-7.0 | 7.0-11.0 | 1.5 Max |

| II | A | 12Kr | 2.0-3.3 | 2.0 Max | 1.5 Max | 0.40-0.60 | 11.0-14.0 | 3.0 Max |

| II | B | 15CrMo | 2.0-3.3 | 2.0 Max | 1.5 Max | 0.80-1.20 | 14.0-18.0 | 3.0 Max |

| II | D | 20CrMo | 2.8-3.3 | 2.0 Max | 1.0-2.2 | 0.80-1.20 | 18.0-23.0 | 3.0 Max |

| III | A | 25Kr | 2.8-3.3 | 2.0 Max | 1.5 Max | 0.40-0.60 | 23.0-30.0 | 3.0 Max |

Microstructure ya High Chromium White Iron

Ceramic-Metal Composite Material (CMC)

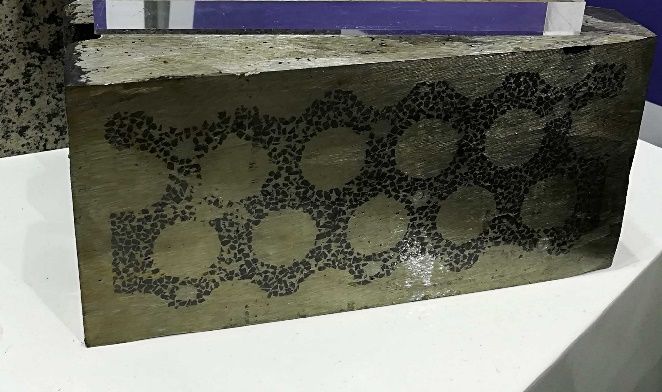

CMC ndi chinthu chosamva kuvala chomwe chimaphatikiza kulimba kwazitsulo zachitsulo (chitsulo chamartensitic kapena chitsulo chachitsulo cha chromium chapamwamba) ndi kuuma kwambiri kwa mafakitale a ceramic. Tinthu tating'ono tating'ono tating'ono tating'ono timapangidwa mwapadera kuti tipange porous thupi la ceramic particles. Chitsulo chosungunula chimalowa kwathunthu muzitsulo za ceramic poyatsira ndikuphatikizana bwino ndi mbiya.

Mapangidwe awa amatha kupititsa patsogolo magwiridwe antchito odana ndi kuvala kwa nkhope yogwira ntchito; panthawi imodzimodziyo, thupi lalikulu la nkhonya kapena nyundo likadali lopangidwa ndi chitsulo kuti liwonetsetse kuti likugwira ntchito bwino, kuthetsa bwino kutsutsana pakati pa kuvala kukana ndi kukana kukhudzidwa, ndipo kungasinthidwe kuzinthu zosiyanasiyana zogwirira ntchito. Zimatsegula gawo latsopano la kusankha kwa zida zopangira zovala zapamwamba kwa ogwiritsa ntchito ambiri, ndikupanga phindu labwino pazachuma.

a.Martensitic Steel + Ceramic

Poyerekeza ndi bar wamba ya martensitic blower, nyundo ya martensitic ceramic blown imakhala yolimba kwambiri pamavalidwe ake, koma kukana kwa nyundo yowomba sikuchepa. M'malo ogwirira ntchito, bar ya martensitic ceramic blower imatha kukhala m'malo mwa pulogalamuyo ndipo nthawi zambiri imatha kupeza pafupifupi ka 2 kapena moyo wautali wautumiki.

b.High Chromium White Iron +Ceramic

Ngakhale chitsulo chowombera chapamwamba cha chromium chimakhala kale ndi kukana kwamphamvu kwambiri, mukaphwanya zida zolimba kwambiri, monga granite, mipiringidzo yosamva kuvala nthawi zambiri imagwiritsidwa ntchito kutalikitsa moyo wawo wogwira ntchito. Pamenepa, chitsulo chopangidwa ndi chromium chapamwamba chokhala ndi chitsulo choyikirapo cha ceramic ndi njira yabwinoko. Chifukwa cha kuyika kwa zida zadothi, kuuma kwa nyundo yowomba kumawonjezekanso, ndipo kukana kwake kumayenda bwino, nthawi zambiri 2 kapena moyo wautali wautumiki kuposa chitsulo choyera cha chromium.

Ubwino wa Ceramic-Metal Composite Material (CMC)

(1) Olimba koma osapunthwa, olimba komanso osamva kuvala, kukwaniritsa kulimba kwapawiri komanso kulimba kwambiri;

(2) Ceramic kuuma ndi 2100HV, ndi kuvala kukana akhoza kufika 3 mpaka 4 nthawi wamba aloyi zipangizo;

(3) Mapangidwe amunthu payekha, mzere womveka bwino wovala;

(4) Moyo wautali wautumiki komanso phindu lalikulu lazachuma.

Product Parameter

| Makina a Brand | Chitsanzo cha makina |

| Metso | Mtengo wa LT-NP1007 |

| Mtengo wa LT-NP1110 | |

| Mtengo wa LT-NP1213 | |

| LT-NP 1315/1415 | |

| LT-NP 1520/1620 | |

| Hazemag | 1022 HAZ791-2 HAZ879 HAZ790 HAZ893 HAZ975 HAZ817 |

| 1313 HAZ796 HAZ857 HAZ832 HAZ879 HAZ764 HAZ1073 | |

| 1320 HAZ1025 HAZ804 HAZ789 HAZ878 HAZ800A HAZ1077 | |

| 1515 HAZ814 HAZ868 HAZ1085 HAZ866 HAZ850 HAZ804 | |

| 791 HAZ565 HAZ667 HAZ1023 HAZ811 HAZ793 HAZ1096 | |

| 789 HAZ815 HAZ814 HAZ764 HAZ810 HAZ797 HAZ1022 | |

| Sandvik | QI341 (QI240) |

| QI441(QI440) | |

| QI340 (I-C13) | |

| Chithunzi cha CI124 | |

| CI224 | |

| Kleemann | MR110 EVO |

| MR130 EVO | |

| MR100Z | |

| MR122Z | |

| Terex Pegson | XH250 (CR004-012-001) |

| XH320-chatsopano | |

| Zithunzi za XH320 | |

| 1412 (XH500) | |

| 428 Tracpactor 4242 (300 high) | |

| Powerscreen | Trackpactor 320 |

| Terex Finlay | I-100 |

| I-110 | |

| I-120 | |

| I-130 | |

| I-140 | |

| Rubblemaster | RM60 |

| RM70 | |

| RM80 | |

| RM100 | |

| RM120 | |

| Tesab | Mtengo wa RK-623 |

| Chithunzi cha RK-1012 | |

| Extec | C13 |

| Telsmith | 6060 |

| Keestrack | R3 |

| R5 | |

| McCloskey | ndi44 |

| ndi 54 | |

| Lippmann | 4248 |

| Mphungu | 1400 |

| 1200 | |

| Womenya | 907 |

| 1112/1312 -100mm | |

| 1112/1312 -120mm | |

| 1315 | |

| Kumbee | No1 |

| No2 | |

| Shanghai Shanbao | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| SBM/Henan Liming/Shanghai Zenith | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| PFW-1214 | |

| PFW-1315 |