Chitsulo cha manganese chasintha zitsulo ndi mafakitale olemera ndi mphamvu zake zapadera komanso kulimba kwake. Wodziwika ndi Sir Robert Hadfield mu 1882, alloy iyi imaphatikiza chitsulo, carbon, ndi manganese kupanga zinthu zomwe zimasiyana ndi zina zonse. Kuthekera kwake kwapadera kowumitsa pansi kwapangitsa kuti ikhale yosinthira zida, makina, ndi ntchito zomanga.

Zodabwitsa za chitsulo cha manganese zimachokera ku ntchito yofunika kwambiri ya manganese pakupanga zitsulo. Sikuti amangochotsa zonyansa monga sulfure ndi mpweya, komanso amathandizira kwambiri kuuma komanso kukana kuvala. M'kupita kwa nthawi, kupita patsogolo monga chithandizo cha kutentha ndi njira zamakono zopangira zakhala zikukulitsa kuthekera kwachitsulo cha manganese, mbale yachitsulo ya manganese,ndizitsulo za manganese.

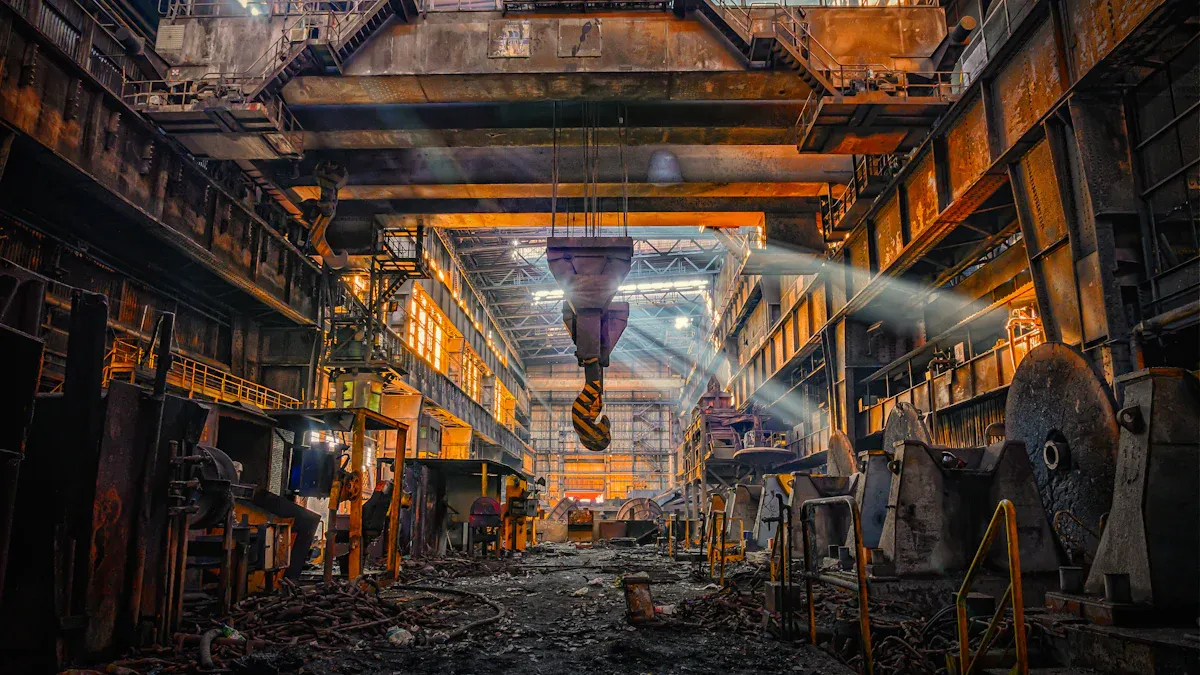

Masiku ano, manganese zitsulo ndimbale yazitsulo za manganesepitilizani kukhala ngati zida zoyambira m'mafakitale omwe amafuna kukana kwambiri, kuphatikiza migodi ndi njanji.

Zofunika Kwambiri

- Chitsulo cha manganeseidapangidwa ndi Sir Robert Hadfield mu 1882.

- Ndi yamphamvu kwambiri ndipo imakhala yolimba ikamenyedwa, ndikupangitsa kuti ikhale yabwino pantchito zovuta.

- Njira ya Bessemer idapangitsa chitsulo cha manganese kukhala bwino pochotsa zonyansa.

- Zimenezi zinapangitsanso kuti chitsulocho chikhale cholimba komanso chokhalitsa.

- Chitsulo cha Manganese chimagwiritsidwa ntchito mumigodi, njanji, ndi zomangamanga chifukwa cha iziamakana kuvala.

- Kulimba kwake kumathandizira kuchepetsa mtengo wokonzanso ndikupanga zida kukhala nthawi yayitali.

- Njira zatsopano zophatikizira ma alloys ndikupanga zitsulo kupititsa patsogolo ntchito zake lero.

- Kubwezeretsanso chitsulo cha manganese ndikofunikira pakupulumutsa chuma ndikuthandizira dziko lapansi.

Chiyambi cha Zitsulo za Manganese

Kupeza kwa Sir Robert Hadfield

Nkhani ya chitsulo cha manganese imayamba ndi Sir Robert Hadfield, katswiri wa zitsulo wa ku Britain yemwe anatulukira zinthu zochititsa chidwi kwambiri mu 1882. Anapeza kuti kuwonjezera manganese ku chitsulo kunapanga aloyi yokhala ndi katundu wodabwitsa. Mosiyana ndi chitsulo chodziwika bwino, zinthu zatsopanozi zinali zolimba komanso zolimba, zomwe zimapangitsa kuti zikhale zoyenera kugwiritsa ntchito kwambiri.

Ntchito ya Hadfield inalibe zovuta. Kumayambiriro, adawona kuti zitsulo za manganese zimatsutsana ndi makina ndipo sizikhoza kutsekedwa, zomwe zinapangitsa kuti zikhale zovuta kugwira ntchito. Komabe, zopinga zimenezi sizinamlepheretse. M'malo mwake, adawonetsa mawonekedwe apadera a alloy ndi kuthekera kwake kusintha mafakitale.

- Kulimba kwachitsulo cha manganese ndi kuuma kwake kumasiyanitsa ndi zinthu zina.

- Zomwe Hadfield adapeza zidagogomezera manganese ngati chinthu chofunikira kwambiri pamikhalidwe yodabwitsayi.

Zoyeserera Zoyambirira ndi Kukula kwa Aloyi

Kupezeka kwa Hadfield kudapangitsa kuti ayesetse kuyesa kukonzanso alloy ndikumvetsetsa zomwe amachita. Ofufuza adayang'ana momwe manganese amalumikizirana ndi zinthu zina monga mpweya ndi chitsulo. Maphunziro oyambirirawa anayala maziko a zitsulo za manganese zomwe tikuzidziwa lero.

Chizoloŵezi choyambirira chogwiritsa ntchito zitsulo za manganese kuchokera m'chaka cha 1887 kupita m'tsogolo chinali kutenthetsa ma ingots otentha kwambiri kuposa kutentha kumene a Potter akutchula. Kalekale chaka cha 1900 chisanafike matani masauzande ambiri a zinthu zopeka ndi zopindidwa zoterozo zinapangidwa ndi kugwiritsidwa ntchito. Mu pepala loperekedwa ku Institute ili ndi wolemba mu 1893, lotchedwa Iron Alloys, ndi Special Reference to Manganese Steel, zonse ndi zithunzi zikuwonetsedwa za chitsulo cha manganese chopangidwa mu ma axle a njanji ndikugubuduza matayala anjanji.

Pamene ofufuza adayesa, adapeza zambiri zochititsa chidwi za kusintha kwa gawo la alloy ndi microstructure. Mwachitsanzo, kafukufuku wina adafufuza aloyi yapakati-manganese yopangidwira kupanga. Zomwe zapezazi zidawonetsa momwe kuchuluka kwa kutentha ndi nthawi yonyowa kumakhudzira zinthu zakuthupi:

| Zotsatira | Kufotokozera |

|---|---|

| Kusintha kwa Gawo | Kafukufukuyu adayang'ana pa kusintha kwa gawo mu aloyi yapakati-Mn, makamaka 0.19C-5.4Mn-0.87Si-1Al, yopangidwira forgings. |

| Zosagwirizana | Kafukufukuyu adawonetsa kusagwirizana pakati pa zoyeserera za thermodynamic ndi zotsatira zoyeserera, ndikugogomezera kufunikira koganizira mozama za kutentha, nthawi yonyowa, ndi mawonekedwe oyambira. |

Kuyesera kumeneku kunathandiza kuyeretsa zitsulo za manganese, zomwe zimapangitsa kuti zikhale zodalirika komanso zogwiritsidwa ntchito mosiyanasiyana pamakampani.

Patenting ndi Kugwiritsa Ntchito Koyamba

Ntchito ya Hadfield inafika pachimake pakupanga patenti yachitsulo cha manganesemu 1883. Ichi chinali chiyambi cha ulendo wake wa ntchito zothandiza. Kutha kuuma kwa alloy pansi pa mphamvu kunapangitsa kuti ikhale yosintha kwambiri m'mafakitale monga migodi ndi njanji.

Chimodzi mwazogwiritsidwa ntchito koyamba kwa chitsulo cha manganese chinali mumayendedwe anjanji ndi ma axles. Kulimba kwake komanso kukana kuvala kunapangitsa kuti ikhale yabwino kunyamula katundu wolemera komanso kukangana kosalekeza kwa masitima. Patapita nthawi, opanga anayamba kugwiritsa ntchito kwa enazida zamphamvu kwambirindi makina, kulimbikitsanso malo ake m'mbiri ya mafakitale.

Zatsopano za Hadfield sizinangopanga zatsopano; chinatsegula chitseko cha nyengo yatsopano ya metallurgy. Chitsulo cha manganese chinakhala chizindikiro cha kupita patsogolo, kutsimikizira kuti sayansi ndi mafakitale amatha kugwira ntchito limodzi kuti athetse mavuto enieni padziko lapansi.

Kupititsa patsogolo mu Manganese Steel Technology

Njira ya Bessemer ndi Ntchito Yake

TheNjira ya Bessemeradachita mbali yofunika kwambiri pakukulitsa chitsulo choyambirira cha manganese. Njira yatsopano yopangira zitsulo imeneyi, yomwe inayambika pakati pa zaka za m'ma 1800, inalola opanga kupanga zitsulo bwino pochotsa zonyansa monga carbon ndi silicon. Sir Robert Hadfield atayesa manganese muzitsulo, njira ya Bessemer inakhala chida chachikulu choyenga alloy.

Pophatikiza manganese munjirayi, opanga zitsulo amatha kupanga zinthu zokhala ndi mphamvu komanso zolimba. Njirayi inathandizanso kuchotsa sulfure ndi mpweya, zomwe nthawi zambiri zinkafooketsa zitsulo zachikhalidwe. Kupambana kumeneku kunakhazikitsa maziko ovomerezeka a chitsulo cha manganese m'mafakitale.

Katundu Woumitsa Ntchito Afotokozedwa

Chimodzi mwazinthu zochititsa chidwi kwambiri za chitsulo cha manganese ndikutha kuuma pansi. Katunduyu, womwe umadziwika kuti kuumitsa ntchito, umachitika pamene zinthuzo zimawonongeka. Pamene pamwamba pamakhala nkhawa, imakhala yolimba komanso yosamva kuvala.

Kafukufuku wasonyeza kuti izi zimakhudzidwa ndi zinthu monga kutentha ndi microstructure yazinthu. Mwachitsanzo, kafukufuku wazitsulo za carbon low, high-manganese adawonetsa kuti kusintha kwa mawotchi ndi martensitic kumawonjezera mphamvu ndi ductility.

| Mbali | Kufotokozera |

|---|---|

| Zakuthupi | Zitsulo za Low-C high-manganese |

| Kutentha kwa Deformation | -40 °C, 20 °C, 200 °C |

| Zowonera | Kusintha kwapang'onopang'ono komanso kuphatikizika kwamakina kumawonjezera mphamvu. |

| Zotsatira | Kutentha kumakhudza khalidwe loumitsa zovuta komanso kusintha kwa microstructure. |

Katundu wapaderawa amapangitsa chitsulo cha manganese kukhala choyenera kwa malo okhala ndi mphamvu zambiri monga migodi ndi zomangamanga.

Kusintha kwa Mapangidwe a Aloyi

Kwa zaka zambiri, ofufuza ateroanakonza kapangidwechitsulo cha manganese kuti chiwonjezere ntchito zake. Kuphatikiza kwa zinthu monga aluminiyamu ndi silicon kwadzetsa kupita patsogolo kwakukulu. Mwachitsanzo, kuchuluka kwa aluminiyumu kumawonjezera mphamvu zokolola komanso kukana kuvala, ngakhale kumachepetsa ductility.

| Kupanga kwa Aloyi | Kutentha kwa Chithandizo cha Kutentha | Valani Kukaniza | Zotsatira |

|---|---|---|---|

| Silikoni | 700 ° C | Kuwongoleredwa | Kukana kuvala kwabwino kwambiri pansi pa katundu wambiri. |

| Chitsulo Chapakati cha Manganese | Zosiyanasiyana | Kuwunikidwa | Framework yogwirizanitsa kapangidwe ndi katundu. |

Kusintha kumeneku kwapangitsa kuti chitsulo cha manganese chizigwira ntchito mosiyanasiyana, kuwonetsetsa kuti chikhalabe mwala wapangodya wamakampani amakono.

Ntchito Zamakampani a Manganese Steel

Zida za Migodi ndi Kugwetsa miyala

Chitsulo cha manganese chimagwira ntchito yofunika kwambiri pakukumba ndi kukumba miyala. Kukana kwake kuvala kwambiri komanso kutha kuumitsa kumapangitsa kuti ikhale yopangira zida zomwe zimakumana ndi zovuta tsiku lililonse. Zida ndi makina m'mafakitalewa nthawi zambiri amalimbana ndi zinthu zowononga, katundu wolemetsa, komanso kukangana kosalekeza. Chitsulo cha manganese chimakwera pamavuto, kukulitsa moyo wa zida ndikuchepetsa mtengo wokonza.

Nazi zina zomwe zimagwiritsidwa ntchito nthawi zambiri:

- Crusher nsagwada: Zigawozi zimaphwanya miyala ndi miyala, kupirira kupsinjika kwakukulu ndi kukhudzidwa. Chitsulo cha manganese chimapangitsa kuti azikhala nthawi yayitali.

- Zojambula za Grizzly: Zomwe zimagwiritsidwa ntchito posankha zida, zowonera izi zimapindula ndi kulimba kwachitsulo cha manganese komanso kukana kuvala.

- Miyala ya miyala: Njirazi zimatsogolera zida kudzera pamakina, pomwe chitsulo cha manganese chimalepheretsa kukokoloka kwa madzi nthawi zonse.

- Zidebe za fosholo: M’migodi, zidebe za fosholo zimanyamula miyala ndi zinyalala zolemera. Chitsulo cha manganese chimawapangitsa kukhala olimba komanso odalirika.

Pogwiritsa ntchito chitsulo cha manganese pakugwiritsa ntchito izi, mafakitale amapulumutsa nthawi ndi ndalama ndikusunga bwino. Makhalidwe ake apadera amapangitsa kuti ikhale yofunikira kwambiri pazida zamigodi ndi miyala.

Sitima zapanjanji ndi Makina Olemera

Misewu ya njanji imadalira chitsulo cha manganese pamayendedwe awo ndi zigawo zake. Kulimba kwa zinthuzi komanso kusamva bwino kwa zinthuzi kumapangitsa kuti zikhale zabwino kwambiri pothana ndi kukangana kosalekeza ndi katundu wolemera wa masitima apamtunda. Kukula kwapadziko lonse ndi kusinthika kwa njanji zapadziko lonse lapansi kwawonjezera kufunika kwake.

Malipoti ochokera kumsika wachitsulo wa austenitic manganese akuwonetsa kugwiritsidwa ntchito kwake kwakukulu m'gawo la njanji. Opanga amachigwiritsa ntchito kupanga mayendedwe okhazikika, masiwichi, ndi kuwoloka komwe kumatha kupirira kukhudzidwa mobwerezabwereza. Kukhoza kwake kupirira mikhalidwe imeneyi kumapangitsa kuti ntchito ziziyenda bwino komanso zimachepetsa kufunika kosintha pafupipafupi.

Kukula kwamakampani anjanji kwalimbikitsanso kufunikira kwa chitsulo cha manganese pamakina olemera. Ma locomotives ndi magalimoto onyamula katundu amafunikira zida zomwe zimatha kuthana ndi kupsinjika kwakukulu komanso kukhudzidwa. Chitsulo cha manganese chimapereka magwiridwe antchito osayerekezeka, ndikupangitsa kukhala chisankho chokondedwa pakugwiritsa ntchito izi.

Kuyika ndalama muzinthu zoyendera kukupitilizabe kupititsa patsogolo luso laukadaulo wazitsulo za manganese. Pamene njanji ikukulirakulira, nkhaniyi imakhalabe mwala wapangodya wamakampani, kuonetsetsa kuti ntchitoyo ndi yodalirika komanso yodalirika.

Zomangamanga ndi Zida Zapamwamba

Malo omanga ndi olimba, ndipo zida zomwe zimagwiritsidwa ntchito pamenepo ziyenera kukhala zolimba kwambiri. Chitsulo cha manganese chimawala m'munda uno, kupereka kukhazikika kosayerekezeka komanso kukana mphamvu. Kuyambira zida zogwetsera mpaka mano ofukula, ntchito zake ndi zazikulu komanso zosiyanasiyana.

Tengani zida zamphamvu kwambiri, mwachitsanzo. Mabala a Jackhammer ndi m'mphepete mwake amakumana ndi kupsinjika nthawi zonse mukamagwiritsa ntchito. Chitsulo cha manganese chimapangitsa kuti azikhala akuthwa komanso akugwira ntchito, ngakhale atakhala nthawi yayitali pamalo olimba. Momwemonso, makina omanga monga ma bulldozer ndi zonyamula katundu amapindula ndi kuthekera kwachitsulo kwa manganese kukana kutha ndi kung'ambika.

Kuphatikiza pa zida, chitsulo cha manganese chimagwiritsidwa ntchito pazinthu zamapangidwe. Milatho, ma girders, ndi zinthu zina zonyamula katundu zimadalira mphamvu zake kuti zisunge bata pansi pa katundu wolemera. Kusinthasintha kwake kumapangitsa kukhala chinthu chofunika kwambiri pomanga, kumene kulimba ndi kudalirika sikungakambirane.

Mwa kuphatikiza chitsulo cha manganese muzomangamanga ndi zida zamphamvu kwambiri, mafakitale amatha kuthana ndi ma projekiti ovuta molimba mtima. Makhalidwe ake apadera amapanga zinthu zomwe omanga ndi mainjiniya amakhulupirira.

Kuyerekeza Chitsulo cha Manganese ndi Zida Zina

Ubwino Wokhazikika ndi Kukaniza Kwamphamvu

Chitsulo cha manganese chimadziwika chifukwa cha kukhazikika kwake komanso kuthekera kokana kukhudzidwa. Mapangidwe ake apadera, omwe akuphatikizapokuchuluka kwa manganesendi kaboni, imalola kuti ikhale yolimba pamwamba pomwe ikusunga pachimake cholimba. Kuphatikiza uku kumapangitsa kukhala koyenera kumadera okhudzidwa kwambiri monga migodi ndi zomangamanga.

Mosiyana ndi zinthu zina zambiri, chitsulo cha manganese chimatha kuyamwa mphamvu zambiri pakapanikizika. Katunduyu, yemwe amadziwika kuti kuumitsa ntchito, amawonjezera kukana kwake pakapita nthawi. Mwachitsanzo, pophatikizira kukwapula kapena kupsinjika kwambiri, mawonekedwe ake amakhala olimba mukamagwiritsa ntchito. Komabe, magwiridwe ake amatha kusiyanasiyana malinga ndi momwe zinthu ziliri. Pansi pa katundu wochepa kapena wochepa, chitsulo cha manganese sichingawumitse bwino, chomwe chingachepetse kulimba kwake muzochitika zoterezi.

Kafukufuku akuwonetsa kuti chitsulo cha manganese, chomwe chimatchedwanso chitsulo cha Hadfield, chimaposa zida zina pakukana kuvala pansi pamikhalidwe yayikulu. Kuthekera kwake kukhazikika gawo la austenitic kumathandiziranso kulimba kwake komanso kutsika mtengo poyerekeza ndi ma alloys opangidwa ndi nickel.

Zovuta ndi Zolepheretsa

Ngakhale ndi mphamvu zake, chitsulo cha manganese chili ndi zovuta zina. Nkhani imodzi yayikulu ndi mphamvu zake zoyamba zotsika, zomwe nthawi zambiri zimakhala pakati pa 200 MPa ndi 300 MPa. Ngakhale kuti zinthuzo zimatha kuuma pansi, mphamvu zokolola zochepazi zimatha kupangitsa kuti zisakhale zogwira mtima pamapulogalamu okhala ndi zolemetsa zochepa kapena zokhazikika.

Cholepheretsa china chimakhudza ductility. Kupititsa patsogolo mphamvu ya chitsulo cha manganese pokonza nthawi zambiriamachepetsa kusinthasintha kwake, kupangitsa kuyanjana pakati pa kulimba ndi brittleness. Kuphatikiza apo, magawo ena, monga gawo la hexagonal close-packed (HCP), amatha kupanga panthawi yokonza. Magawo awa amawonjezera chiwopsezo cha fractures, ndikupangitsa kuti ntchito yake ikhale yovuta m'mafakitale ena.

Zida Zopikisana ndi Zatsopano

Kupanga zida zatsopano ndi matekinoloje kwayambitsa mpikisano wachitsulo cha manganese. Kupita patsogolo kwafukufuku wazitsulo kwachititsa kuti pakhale ma alloys apamwamba kwambiri ndi ma composites omwe amatsutsa ulamuliro wake.

- Zatsopano zamakina azitsulo, monga zitsulo zapakatikati za manganese, zimapereka zida zamakina komanso kupulumutsa mtengo pochepetsa ma alloying.

- Ukadaulo wowonjezera wopangira zinthu umathandizira kupanga zida zokhazikika zomwe zimakhala ndi zida zokongoletsedwa kuti zizigwiritsidwa ntchito mwapadera.

- Mafakitale monga zamagalimoto ndi zakuthambo akuyendetsa kufunikira kwa zinthu zopepuka, zamphamvu kwambiri, zomwe nthawi zambiri zimafunikira kuyesedwa kwazitsulo zapamwamba kuti zitsimikizire chitetezo ndi kutsata.

Ngakhale chitsulo cha manganese chikadali mwala wapangodya m'mafakitale olemera, zatsopanozi zikuwonetsa kufunikira kwa kafukufuku wopitilirabe kuti asunge kufunikira kwake pamsika wampikisano.

Chitsulo cha Manganese Masiku Ano ndi Zamtsogolo

Ntchito Zamakono Zamakampani

Chitsulo cha manganese chikupitiriza kusewerantchito yofunika kwambiri m'mafakitale amakono. Kukhalitsa kwake komanso kukana kwamphamvu kumapangitsa kuti ikhale yofunika kwambiri m'magawo monga zomangamanga, mayendedwe, ndi kupanga. Ndipotu, kupanga zitsulo kumapanga 85% mpaka 90% ya zofuna za manganese, kuwonetsa kufunikira kwake popanga ma alloys amphamvu kwambiri.

| Makampani / Ntchito | Peresenti ya Kufunika kwa Manganese |

|---|---|

| Kupanga zitsulo | 85% mpaka 90% |

| Zomangamanga, Makina, Magalimoto | Kugwiritsa ntchito komaliza |

| Ntchito Nonmetallurgiska | Zomerani feteleza, chakudya cha ziweto, mitundu ya njerwa |

Kupitilira ntchito zachikhalidwe, ma aloyi a manganese akuchulukirachulukira pamsika wamagalimoto. Zida zopepuka zopangidwa ndi chitsulo cha manganese zimathandizira kukonza bwino mafuta komanso chitetezo. Kusinthaku kumagwirizana ndi kufunikira kokulirapo kwa njira zopulumutsira mphamvu pamayendedwe.

Kusinthasintha kwachitsulo cha manganese kumatsimikizira kufunikira kwake m'mafakitale omwe amaika patsogolo mphamvu, kulimba, ndi luso.

Khama lokhazikika komanso lobwezeretsanso

Kukhazikika kwakhala chinthu chofunikira kwambiri pamakampani opanga zitsulo, ndipo chitsulo cha manganese ndi chimodzimodzi. Kubwezeretsanso kumagwira ntchito yofunika kwambiri pochepetsa zinyalala komanso kusunga zinthu. Ma metric monga End-of-Life Recycling Rate (EoL-RR) ndi Recycling Process Efficiency Rate (RPER) amawunika momwe zida zotsalira zimagwiritsidwira ntchito moyenera.

| Chizindikiro | Chidule | Kufotokozera mwachidule |

|---|---|---|

| Chiwopsezo chonse chobwezeretsanso zinthu zakale | TS-RIR | Imayesa kachigawo kakang'ono ka zinthu zonse zomwe zingalowetsedwenso kuti zibwezeredwenso pazowonjezera zonse. |

| Kutha kwa moyo wobwezeretsanso | EoL-RR | Imayezera kachigawo kakang'ono ka zinyalala zakale zobwezerezedwanso pa ndalama zonse zomwe zimapangidwa pachaka. |

| Kubwezeretsanso ndondomeko yoyenera mlingo | RPER | Imayesa kachigawo kakang'ono ka zinyalala zonse zobwezerezedwanso potengera zonse zomwe zidapangidwa kuti zibwezeretsedwenso. |

Kuyesetsa kukonzanso zitsulo za manganese sikungochepetsa kuwonongeka kwa chilengedwe komanso kumapangitsa kuti pakhale mphamvu zokwanira zopezera zinthu. Ntchitozi zikugwirizana ndi zolinga zapadziko lonse zachitukuko chokhazikika, kuwonetsetsa kuti mafakitale angathe kukwaniritsa zofuna zamtsogolo moyenera.

Emerging Technologies ndi Applications

Tsogolo la chitsulo cha manganese likuwoneka bwino, chifukwa cha kupita patsogolo kwaukadaulo komanso kusintha kwa zosowa zamafakitale. Ku South Korea, msika wa manganese boron zitsulo ukukula chifukwa cha ntchito zake m'magalimoto ndi zomangamanga. Kukwera kwa magalimoto amagetsi kwawonjezera kufunikira kwa zida zatsopano, ndikutsegulira njira yogwiritsira ntchito chitsulo chatsopano cha manganese.

- Chitsulo cha manganese chimathandizira matekinoloje okhazikika ngati ma electrolytic manganese madzi otayira.

- Zimagwira ntchito yofunika kwambiri pamakina osungira mphamvu komanso kugwiritsa ntchito biomedical.

- Kuphatikizika ndi kupeza m'gawo lazitsulo kumayendetsa luso komanso kukula kwa msika.

Pamene mafakitale akufufuza zotheka zatsopano,chitsulo cha manganese chimakhalabe mwala wapangodyaza kupita patsogolo. Zochita zake zambiri zimatsimikizira kuti ipitilizabe kutengera zomwe zikuchitika komanso matekinoloje.

Chitsulo cha manganese chasiya chizindikiro chosazikika pazitsulo ndi mafakitale kuyambira pomwe zidapezeka m'zaka za zana la 19. Ntchito yochita upainiya ya Sir Robert Hadfield inayambitsa zinthu zomwe zingalimbane ndi mphamvu, kusintha machitidwe a migodi, njanji, ndi zomangamanga. M'kupita kwa nthawi, kupita patsogolo monga chithandizo cha kutentha ndi kukonzanso ma alloy kwakweza mphamvu zake zamakina, kuwonetsetsa kuti zimapitilirabe kufunikira kwake m'malo okhala ndi mphamvu zambiri.

Zitsulo zapakatikati-manganese, zokhala ndi nyimbo zoyambira 3% mpaka 10% manganese, zimawonetsa mawonekedwe apadera komanso mphamvu zapadera. Njira zopangira monga Deforming and Partitioning (D&P) zapangitsa kuti zokolola zikhale zowoneka bwino, zomwe zimawapangitsa kukhala abwino pakugwiritsa ntchito atolankhani.

Kuyang'ana m'tsogolo, makampaniwa akukumana ndi zovuta monga kukhudzidwa kwa chilengedwe komanso kukwera mtengo kwa ntchito. Komabe, mipata imakhala yochuluka. Kuchuluka kwa kukwera kwa ma alloys opangidwa ndi manganese pakupanga zitsulo komanso njira zosungiramo mphamvu zowonjezera kukuwonetsa kufunikira kwake.

| Gulu | Tsatanetsatane |

|---|---|

| Madalaivala Akuluakulu | - Kukula kutengera magalimoto amagetsi kwa mabatire a lithiamu-ion. |

| - Kupititsa patsogolo ntchito zachitukuko padziko lonse lapansi. | |

| Zoletsa Zomwe Zilipo | - Ziwopsezo za thanzi zomwe zimagwirizanitsidwa ndi kuwonekera kwa manganese. |

| Mwayi Ukubwera | -Kupita patsogolo kwaukadaulo wamigodi ndi machitidwe okhazikika. |

Kuthekera kwachitsulo cha manganese kutengera matekinoloje omwe akubwera kumatsimikizira malo ake m'tsogolomu. Kuchokera ku machitidwe osungira mphamvu kupita kuzitsulo zapamwamba, kusinthasintha kwake kukupitiriza kuyendetsa luso komanso kukhazikika.

FAQ

Nchiyani chimapangitsa chitsulo cha manganese kukhala chapadera kwambiri?

Chitsulo cha manganese ndi chapaderachifukwa zimauma pansi pa mphamvu. Katunduyu, wotchedwa kulimbikira ntchito, amapangitsa kuti ikhale yolimba kwambiri ikagwiritsidwa ntchito. Ndiwoyenera ku zida zamphamvu kwambiri komanso makina omwe amakumana ndi kuwonongeka kosalekeza.

Kodi chitsulo cha manganese chingagwiritsidwenso ntchito?

Inde! Kubwezeretsanso chitsulo cha manganese kumathandiza kuchepetsa zinyalala ndikusunga zinthu. Mafakitale amagwiritsanso ntchito zinthu zakale kuti apange zinthu zatsopano, zomwe zimapangitsa kuti zikhale zokomera chilengedwe kupanga zokhazikika.

Kodi chitsulo cha manganese chimagwiritsidwa ntchito pati?

Mupeza chitsulo cha manganese mu zida zamigodi, njanji zanjanji, ndi zida zomangira. Kukhazikika kwake komanso kukana kukhudzidwa kumapangitsa kukhala koyenera kwa malo omwe zida zimakumana ndi kupsinjika kwambiri.

Kodi chitsulo cha manganese ndichabwino kuposa zida zina?

Pazovuta kwambiri, chitsulo cha manganese chimaposa zida zambiri. Ndiwolimba ndipo umatenga nthawi yayitali. Komabe, sizothandiza pazowonjezera zokhazikika kapena zopepuka, pomwe ma aloyi ena amatha kugwira bwino ntchito.

Kodi chitsulo cha manganese chimathandiza bwanji mafakitale kusunga ndalama?

Kukana kwake kuvalaamachepetsa kufunika kosintha pafupipafupi. Mafakitale omwe amagwiritsa ntchito chitsulo cha manganese amawononga ndalama zochepa pakukonza ndi kuchepetsa nthawi, kukulitsa luso komanso kuchepetsa ndalama.

Nthawi yotumiza: Jun-09-2025